Removing 30% of Slurry Pump Inspections

Calculate Health, Remove Inspections

Predict partnered with an Australia mining company in 2021 to optimise their existing maintenance strategies with the help of the health data provided by Predict.

In the first step, Predict analysed the slurry pump system to design an indicator using existing process data to measure the health of the pump. The accuracy of this data was confirmed through two periods where the health measured reflected a relative amount of wear on internal components (throatbush wear pictured).

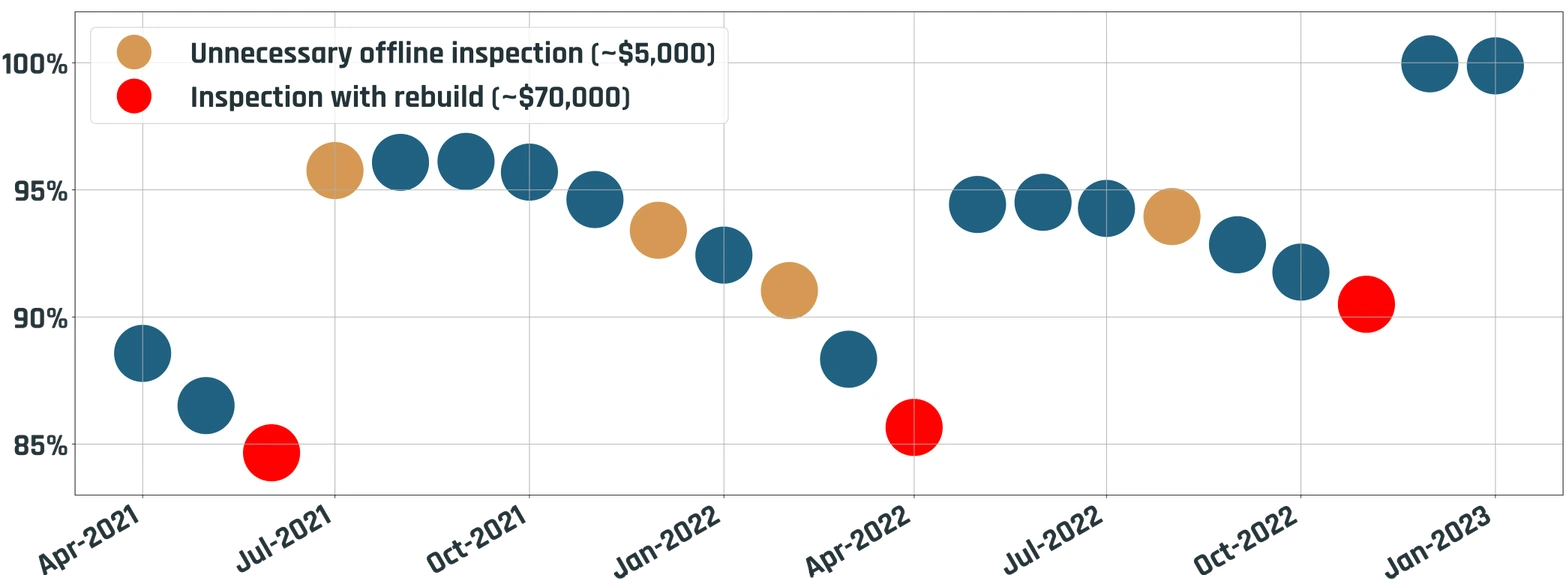

Upon analysis, as much as 30% of the existing scheduled maintenance was performed without any replacement of parts and therefore could now be removed (points in gold).

Slurry Pump Internal Health Calculated by Predict

Time-based schedules require unnecessary inspections because the condition of internal parts is unknown.

Remove unnecessary inspections and extend the life of parts with Predict.

Throathbush at 84% Health →

Extend the Life of Parts

This health data allowed us to track the remaining useful life of internal components to issue health-based maintenance rather than a time-based schedule.

Extending the time between rebuilds for a single slurry pump by as little as 30 days results in a cost saving of 16% – over $20,000 per year per pump.

← Throathbush at 91% Health